If your health and safety measures in the workplace aren't performing, then the repercussions can be significant, but how do we measure this?

Fines, penalties, and prosecutions can result from statutory breaches, but there can be a wider impact on employer/employee relations, operational efficiency, opportunity cost, customer relationships, and reputation. Ultimately, it's the value of the business. So why wouldn't you want to know how you are performing, and if you do, how would you go about it?

Following the coronavirus pandemic, you may also be considering a range of additional health and safety measures in the workplace – from social distancing and the availability of anti-bacterial hand sanitisers to creating procedures for those employees with existing health conditions or influencing safe behaviour in the workforce following the enforced time away from work.

Measuring Safety Performance

Measurement is an important step in any management process and is the basis of continual improvement - it is a key element in the effectiveness of health and safety procedures. If there is no reliable information to inform managers how well their health and safety risks are controlled, how can it be managed?

Measurement is an accepted part of the 'plan-do-check-act' management process. Measuring performance is as much part of a health and safety management system as financial, production, or service delivery management. The HSG 65 framework for managing health and safety at work shows where measuring performance fits within the overall health and safety management system.

Why are performance metrics around health & safety so important?

Health and safety differ from many areas measured by managers because success results in the absence of an outcome (injuries or ill health) rather than a presence. But a low injury or ill-health rate, even over a period of years, is no guarantee that risks are being controlled and will not lead to injuries or ill health in the future. This is particularly true in business where there is a low probability of accidents, but major hazards are present.

Here the historical record can be a deceptive indicator of safety performance; an absence of accidents does not mean that an environment is safe.

This type of data, known as LAG indicators, tells us something after the event and is known as a REACTIVE indicator. These are important performance measures, but they don't allow us to influence our safety environment. Given the potential consequences of events, it is also helpful to look at LEAD Indicators. These point to issues that could give rise to an event and are PROACTIVE Indicators.

What lead indicators might I want to look at?

If we step back and consider the health and safety process, health and safety risk assessment is the key step. This allows you to identify the hazards and define the control measures and successfully implement and maintain these control measures. These could be engineering controls, safe working procedures, safety checklists, training, or PPE that protect the workforce, the public, and the business.

Lead indicators are comprised of 2 types of metrics

- Metrics that tell us about a level of activity that needs to happen as part of our safety organisation and

- Metrics that tell us about the performance of activity within our safety organisation.

So LEAD indicators might be

- How many Risk Assessments have been proactively monitored in a given period against a monitoring regime?

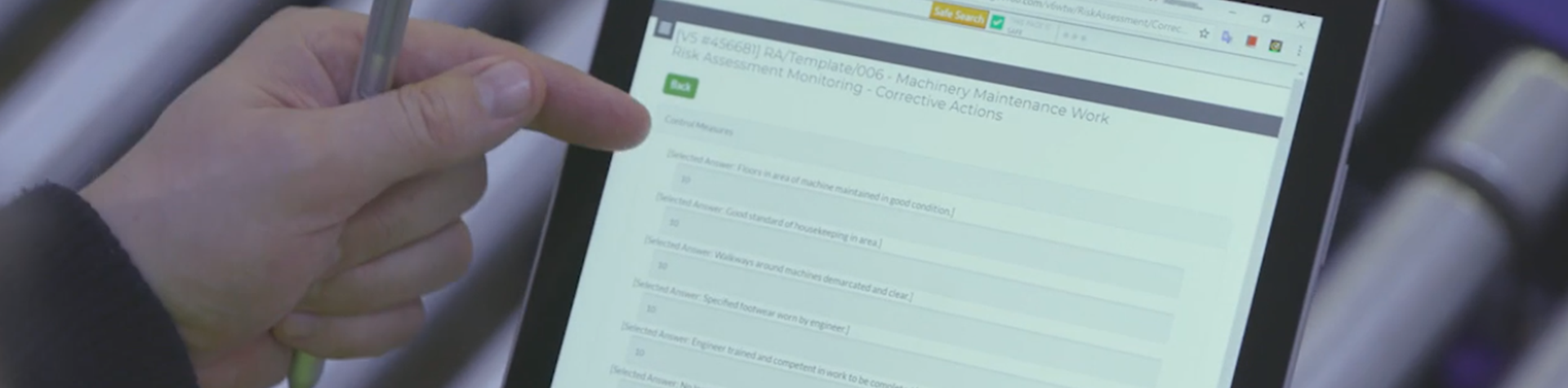

- How many of the control measures defined in a Risk Assessment are in operation and being complied with?

Here are some examples of lead performance metrics

Risk Assessments: If you have a risk assessment which details 20 control measures and only 10 of these are in place, then as a simple measure, you are only achieving a 50% performance against your risk assessment.

Employee training: Training can produce several Lead Indicators such as:

- What % of your training requirements are up-to-date

- If you are testing employees knowledge, what is % competency

- If you use an E-Learning suite like BCarm's and your E-Learning incorporates a self-assessment by the employee, then you can use this to capture discrete and valuable risk sampling

Checklists: % performance of desired outcomes - for example, you could score your safety checklist based on the number of breaches or problems that need rectifying. If a checklist score fails 10 out of 100 items covered, they scored 90%. Maybe a sign was missing, an induction hadn't been carried out, or someone didn't have the right PPE on. If the next time that site is checklist scored, they score 95%, you have measured an improvement.

Audit - Providing it captures both quantitative data can also produce a performance score.

PPE - Your metrics could come from what % of your issued PPE needs to be maintained, replaced, or checked.

Planned, Preventative Maintenance - What % of negative outcomes.

Near Miss/Incident Activity - Measuring the number of near misses reported will give you an indication of whether your workforce has embraced the health and safety measures in the workplace. If you got a lot of reports the first month and hardly any the second, it might mean issues have been resolved. Or it might mean your staff has lost interest. Under-reporting near-misses might indicate a need for further health and safety training, involvement, or improvements to the system itself or its perception from staff.

Hazard spotting - This can indicate engagement from within the business. What you are measuring is not the absence of hazards, but that a target number of hazards are being reported on an ongoing basis. A target of 200 employee identified hazards is the targeted benchmark, and anything below indicates a lack of awareness or engagement.

So, why isn't health and safety performance reporting the norm?

A significant factor can be data capture, and the time it takes, particularly in paper-based systems. Many safety managers wear multiple hats, and time is a precious commodity. H&S Software can provide a solution to this, providing it is designed to produce performance data and not just workflow, document management, or task scheduling. And perhaps the benefits of having such performance data aren't appreciated by the business.

How do I get started?

Performance reporting is built into BCarm management systems, so if you'd like to understand what's possible regarding health and safety measures in the workplace for your individual business needs, get in touch with our team for a free consultation.