Supply chain fragility has become a popular topic, and there have been a number of articles in the press about how JUST IN TIME is moving to JUST IN CASE. In this insight, we explore how companies can build resilience into their supply chain and the 3 key concepts to bear in mind.

Just in Time is great at driving out cost and inefficiencies, but if there isn't enough resilience built into the model, it will not withstand the shocks we have seen in the last few months.

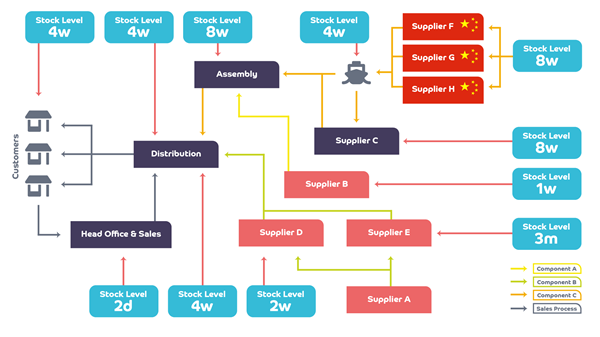

Many businesses have evolved complex supply chains focusing on efficiency, whether that is operational efficiency or capital efficiency, but complex systems, by their nature, can be fragile at the same time if they don't build in resilience.

In “Resilience: Why things bounce back” by Andrew Zolli and Ann Marie Healy, they describe systems as “Robust-yet-Fragile”, highly resilient in anticipated dangers but highly susceptible to unanticipated threats and the now more familiar Black Swan events.

Building resilience is at the core of Business Continuity, which many confuse with Disaster Recovery: Business Continuity Planning is about the ability to continue delivering your products and services regardless of what your organisation experiences, whereas Disaster Recovery is when it experiences a major event.

Supply Chains create further challenges with both globalisation and the lack of visibility and control over risks.

Tackling Resilience can appear daunting, but 3 simple Continuity Planning concepts can get you there.

1. Tolerance for Disruption

Quite simply, if you are unable to deliver your products/services, how long before you lose customers, your business is irreparably damaged, or you run out of cash; also known as the Maximum Tolerable Period of Disruption or MTPD.

This is the most important question to ask as you embark on the BC process as it is simply what your BCMS is designed to avoid you reaching. It sets your Recovery Times Objectives whether that's for your own operations or Suppliers.

This simple question should be at the heart of the supply chain design. If we don’t understand this, we can’t design our supply chain to avoid this happening. There needs to be slack or give in any supply chain, whether that's achieved by using buffer stocks at a diverse site or dual suppliers. It means working with the supply chain to ensure resilience, and that means making business continuity part of the supply chain dialogue.

2. You can't plan for everything; you can plan for anything.

This may sound contradictory, but it’s based on the premise that the cause of disruption is immaterial; it doesn't matter why you don’t have your components or why your supplier is unable to supply; it’s how you re-supply quickly or call upon a buffer stock before your ability to supply your products is impaired.

When we plan for events (everything), it can present us with too much information to tackle so we have to filter this down, usually by assessing the risk and by measuring likelihood vs consequence.

Too many Business Continuity projects get bogged down in this and fall into the trap of “it will never happen”! By taking the Plan for Anything approach removes that potentially dangerous filter and focuses on maintaining the flow of product/service to customers regardless of what events occur. This is how you build in resilience against Black Swan events.

3. It’s all about time.

We deliver our products and services through time; our customers want them in a timeframe, we need our suppliers to deliver their products and services to us in a timeframe.

When you map how you deliver your product/service through time, from your supply chain through to your end customer, then you begin to see different dynamics in play.

This time-based visualisation allows you to identify gaps and points of failure and also priorities, for instance, around high-value customers.

You also begin to think about what you can do to change the timescales that things might be achieved in; We have seen businesses come up with really creative low-cost solutions just because they are changing their view of their business and working with the supply chain to address this as a common issue.

Learn more

If you’re interested in learning more, join a free BCarm Academy virtual sessions which cover a range of risk topics including Business Continiuty. These 30-minute bite-size morning sessions will explore and unravel the main Business Continuity concepts and help increase understanding of how to get started.